The projected growth of the global core materials market is substantial, with estimates indicating a rise from USD 1.6 billion in 2023 to USD 3.0 billion by 2028, representing a compound annual growth rate (CAGR) of 13.5% over the forecast period. The wind energy industry is experiencing a global growth in installations, which is contributing to the surge in demand for core materials. The majority of core materials have an excellent strength-to-weight ratio, which makes it easier to reduce weight while building sandwich composites. Government and energy planner initiatives to diversify energy sources and protect economies from the price instability of fossil fuels are driving growth in the wind energy industry. This pattern emphasizes how competitive wind energy is becoming as a realistic substitute in the world energy market.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=146879627

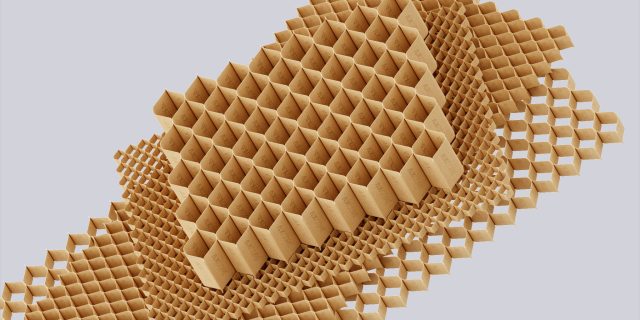

Based on Type, Core materials are categorized into balsa, foam, and honeycomb segments. Foam takes the lead among these and is the most popular option in the core materials industry. It is preferred because of its adaptability and affordability in a range of end-use sectors. Additional categories for foams include PET, PVC, SAN, PMI, PEI, and others. The most common of them is PET foam, which is made from recycled PET bottles and is known for being environmentally friendly. However, balsa wood, from which balsa core is made, has long been used in wind blade and boat building applications.

Based on End-Use Industry, the wind energy, marine, aerospace & military, automotive & transportation, construction, industrial, and other segments (sporting goods and healthcare) comprise the core materials market. The market for core materials was dominated by the wind energy industry. Core materials are essential to many applications in the wind energy sector, such as spinners, nacelles (platforms and coverings), and rotor blades (shear web, shells, and edge close-outs). These core materials are essential to the composite wind blade because they provide the necessary low density, high stiffness, and thickness, which improves performance and longevity.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=146879627

By Region wise, Asia Pacific was the leading market for the core materials market in 2022. Due to its aggressive renewable energy targets and large expenditures in wind power infrastructure, China is becoming one of the region’s most important markets, which has increased demand for core materials to previously unheard-of levels. China’s relentless quest for clean energy solutions has resulted in a significant increase in the production of wind turbine components, particularly rotor blades, nacelles, and spinners—all of which heavily rely on core materials for structural integrity and performance optimization. China is currently the world’s largest market for wind energy installations. Furthermore, the wind energy industries in other Asia Pacific nations, such Japan and India, are expanding significantly, which is fueling the rising need for core materials.

The key players in the core materials market are 3A Composites (Switzerland), Diab Group (Sweden), Gurit (Switzerland), Hexcel Corporation (US), Armacell S.A. (Luxembourg), Euro-Composites S.A. (Luxembourg), and Changzhou Tiansheng New Materials Co. Ltd. (China) among many others.