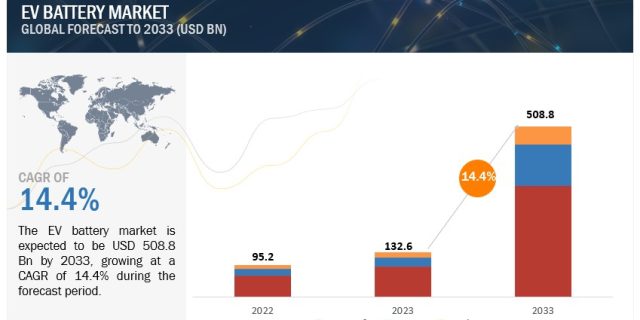

The global EV battery market is projected to grow from USD 132.6 billion in 2023 to USD 508.8 billion by 2033, registering a CAGR of 14.4%.

Recent advancements in the EV market have resulted in the introduction of batteries with higher standards. While these batteries are expected to improve EV performance and range, factors such as the limited range of EVs, the significant charging time required, the high price of EV batteries, and the limited availability of charging stations make users hesitant to choose EVs over ICE vehicles. As a result, EV battery makers are concentrating on overcoming these challenges by developing new batteries with creative, fast, and rapid charging technologies. Besides, there are improvements in manufacturing processes, including automation and novel assembly techniques, which aim to reduce costs and enhance the scalability of battery production. This includes innovations in electrode manufacturing, cell assembly, and pack integration such development is also expected to play a significant role in market growth.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=100188347

Lithium-Ion battery holds the largest market during the forecast period.

In the EV battery market, lithium-ion batteries have the largest market share. Several decades have passed since the development and refinement of lithium-ion battery technology. It is a mature technology with considerable research that has resulted in excellent levels of reliability and safety, making it a popular choice for EV producers. Continuous research and development activities aim to improve lithium-ion battery technology. In the market, incremental advancements in energy density, charging speed, lifetime, and safety features have solidified its supremacy. Additionally, Their decreasing cost is a major factor driving their demand. In June 2023, Toyota announced that it aims to launch next-generation lithium-ion batteries in 2026, offering longer ranges and quicker charging. Vehicles such as the Hyundai IONIQ 6, Nissan Ariva, Genesis GV60, Cadlillac Lyriq Toyota Bz4x, and Chevrolet Silverado EV are popular EVs with lithium-ion batteries launched in 2023. lithium-ion battery is making EVs more affordable and practical for consumers. Also, the expansion of charging infrastructure supports the growth of EVs. As more charging stations become available, consumers are more inclined to switch to EVs, further driving the demand for lithium-ion batteries.

Laser Bonding is the most prominent method in the EV battery markets during the forecast period.

The laser bonding segment is expected to lead the EV battery market during the forecast period. The laser bonding method is mostly preferred due to its non-contact process that enables the welding of dissimilar materials with high precision. It is used to bond the metal components of battery enclosures together. This can create a strong and leak-proof seal that protects the battery cells from the environment. Its benefits, such as improved electric conductivity, enhanced welding quality, and the ability to weld dissimilar metals, make the laser bonding method suitable for EV batteries. The upcoming new Chevrolet Silverado EV is a fully electric pickup truck that is powered by a large battery pack. The battery pack is bonded together using laser welding, which helps to create a strong and reliable bond that is resistant to corrosion. Laser bonding involves a metal ribbon attached to the surface to be welded by irradiating with a laser. The laser causes the ribbon to partially melt, and the ribbon metal gets mixed with the surface metal, thus creating a welded joint/bond. The acceptable temperature in a lithium-ion battery is between 20 ºC and 60 ºC (68 ºF and 140 ºF). Any temperature exceeding that range could lead to degradation in performance and cause thermal runaway. In laser bonding, the heat generated is much lower, which is also an added advantage. As the demand for EVs continues to grow, the demand for laser bonding is also expected to increase. This is due to the many benefits that laser bonding offers, such as improved performance, reduced production time, and increased flexibility.

Asia Pacific is the largest market for EV batteries during the forecast period.

The Asia Pacific EV battery market is led by China, Japan, and South Korea. China is the largest EV battery producer and user globally, and it is dominating the EV market in the region. The government has taken steps, including subsidies for EV buyers, compulsory laws for manufacturers to produce EVs against a particular number of vehicles manufactured, support for installing EV charging points across major cities, and regulations against excessive polluting vehicles. Japan and South Korea have also been growing their markets. Their governments have supported the growth in demand for EVs by installing EV charging stations, setting emission norms, and setting deadlines for shifting to full or hybrid EVs from ICE vehicles. India has undertaken policies to increase EV demand in the market. The new vehicle scrappage policy allows old vehicles to be scrapped for adopting low-emission vehicles.

Key Market Players

The EV battery market is dominated by established players such as CATL (China), LG Energy Solution Ltd. (South Korea), BYD Company Ltd. (China), Panasonic Holdings Corporation (Japan), SK Innovation Co., Ltd. (South Korea) and others. These companies manufacture batteries and develop new technologies.

Request Free Sample Report @ https://www.marketsandmarkets.com/requestsampleNew.asp?id=100188347