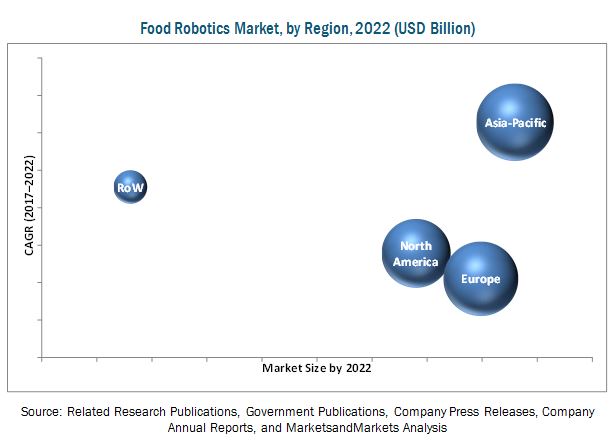

The global food robotics market is projected to reach USD 2.50 billion by 2022, at a CAGR of 12.80% from 2017. Factors such as increasing food safety regulations and the high demand for packaging & re-packaging in food production are expected to increase the demand for food robotics, globally. Furthermore, increasing instances of food contamination through human contact have encouraged manufacturers to employ industrial robots in the food & beverage manufacturing processes. The demand for food robotics is anticipated to increase in the Asia Pacific region, owing to the rapidly growing processed food industry.

With the increasing functionality of robots, more industries such as the food processing industry are adopting automation with low payload robots. Sections such as dairy and bakery in the food & beverage industry are minimizing human contact in the production process in order to comply with health authority standards. There is an opportunity for the food robotics market to grow with the increase in functionality of robots to include packaging, repackaging, and palletizing.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=205881873

Limited skilled workforce is the major restraining factor for the market.

In countries where the food & beverage industry has high potential for growth—such as China, India, and Brazil—there is a skill shortage in this domain. This is because the knowledge of four to five engineering disciplines is required to become an expert in this field, and there is a scarcity of qualified faculty to train in the subjects. Moreover, there are limited branches of engineering that focus on robotics. This is a direct restraining factor for the food robotics market as the development of adequate skilled manpower is likely to be achieved only in the long run.

Most food manufacturers are reluctant to adopt automated processes due to the installation cost over and above the price of the robot. The added cost to turn the individual robots into a comprehensive robotic system, peripheral equipment such as safety barriers, sensors, programmable logic controllers (PLC), human-machine interface (HMI), and safety systems pose challenges for market growth.

Speak to Analyst:

https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=205881873

The Asia-Pacific region is projected to have the highest CAGR from 2017 to 2022

The Asia-Pacific region is projected to be the fastest-growing market for food robotics during the forecast period, as the consumer demands for ready-to-eat products have increased rapidly in the last decade. The key Asia-Pacific markets are Japan, China, Republic of Korea, Indonesia, Taiwan, India, and Rest of Asia- Pacific. The imports of robotics for the food sectors of these countries has increased in the last 5 years. The major factors driving the Asia-Pacific food robotics market is urbanization and the rise in disposable income of consumers, which have led to the growth of packaged food consumption in this region.

The major challenge faced by food robotics manufacturers is the high cost of installing the robotic systems. Most food manufacturers are reluctant to adopt automated processes, due to the installation cost over and above the price of the robot. The added cost to turn individual robots into a comprehensive robotic system comprises the cost of peripheral equipment such as safety barriers and sensors. Such challenges may hamper the food robotics market in the coming years.

The key participants in the food robotics market are the food robotics manufacturers, suppliers, and regulatory bodies. The key players that are profiled in the report include Mitsubishi Electric Corporation (Japan), ABB Group (Switzerland), Kawasaki Heavy Industries Ltd. (Japan), Rockwell Automation Incorporated (U.S.), and FANUC Corporation (Japan). These companies have diversified product portfolios, proprietary technologies, and strong distribution networks and offices at major strategic locations. The other companies profiled are KUKA AG (Germany), Seiko Epson Corporation (Japan), Yaskawa Electric Corporation (Japan), Staubli International Corporation (Switzerland), Mayekawa Mfg. Co., Ltd. (Japan), Universal Robots A/S (Denmark), and Bastian Solutions Inc. (U.S.)