Ion milling is a physical etching technique whereby the ions of inert gas are accelerated from a wide beam ion source onto the surface of a substrate (or coated substrate) in a vacuum, for removing material to some desired depth or under layer through the sputtering effect. Ion milling is the process of removing the top amorphous layer on a material to reveal the pristine sample surface for high-resolution imaging and post-processing. The systems are especially appropriate in research & development, quality control, and low-volume production applications.

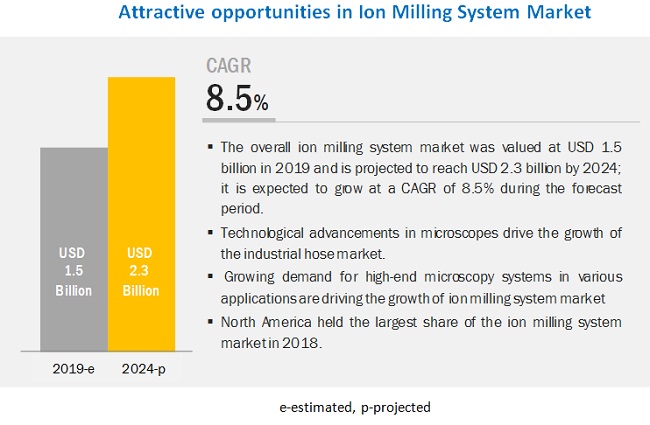

The ion milling system market is estimated to be valued at USD 1.5 billion in 2019 and is projected to reach USD 2.3 billion by 2024; it is expected to grow at a CAGR of 8.5%. Increasing demand for high-end microscopy systems in various applications is expected to fuel the growth of the ion milling system industry during the forecast period.

Download PDF Brochure @

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=102607971

Ion milling systems for SEM electron microscopy is expected to hold the largest market share during the forecast period. SEM produces images by scanning the sample with high-energy electron beams. It involves exposing sample surface to a focused electron beam to produce high-quality images of the surface topography. The growth of the SEM market is fueled by the increasing use of SEM in industrial science as well as in the electronics industry. SEM is used widely in several sub-applications of material science such as metals & metallurgy and polymer science.

The market for ion milling system for polymer sample material is expected to hold the largest share during the forecast period. Polymers are organic compounds with large molecular structures that mainly comprise carbon and hydrogen. Polymers are lightweight, low-cost, and malleable materials, which makes them the most preferred material for many engineering applications. Hence, some of the advantages of polymer sample materials for various applications is expected to boost the market during the forecast period.

Semiconductor manufacturing application is the largest adopter of ion milling systems. In semiconductor fabrication, processes include oxidation, lithography, etching, doping (through vapor phase deposition and ion implantation techniques), and layering (through metallization technique). Metrology and inspection are important for the management of the semiconductor manufacturing process. Hence, the demand for ion millings systems in semiconductor manufacturing is expected to boost market growth during the forecast period.

The ion milling system market in APAC is expected to grow at the highest CAGR during the forecast period. The market for ion milling systems in the region is expected to witness the fastest growth owing to rapid developments in China, Japan, and India. China is likely to offer ample opportunities to the ion milling system market players in the coming years. APAC leads the ion milling system market due to the dynamic changes in terms of receptiveness toward new technologies and advancements in various industry organizations. This region has become a global focal point for major investments and business expansion opportunities.