In recent years, the biopharmaceutical industry has witnessed a paradigm shift towards single-use bioprocessing technologies. These technologies have revolutionized the way biologics and vaccines are manufactured, offering flexibility, efficiency, and reduced risk of cross-contamination compared to traditional stainless-steel equipment. The single-use bioprocessing market has thus emerged as a critical sector within the broader biotechnology landscape, driven by advancements in equipment such as bioreactors, mixers, filtration systems, and chromatography.

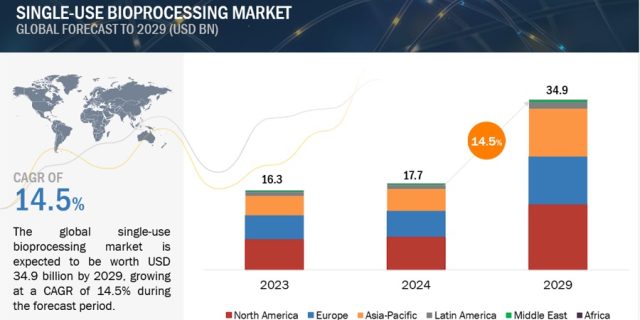

Single Use Bioprocessing Market Size, Share & Trends by Product (Equipment (Bioreactors, Mixers, Filtration, Chromatography) – Global Forecast to 2029.

The size of global single use bioprocessing market in terms of revenue was estimated to be worth $17.7 billion in 2024 and is poised to reach $34.9 billion by 2029, growing at a CAGR of 14.5%.

Download a PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=231651297

Overview of the Single Use Bioprocessing Market

The global single-use bioprocessing market has been experiencing significant growth, propelled by the increasing demand for biopharmaceuticals, personalized medicine, and regulatory support for single-use technologies. According to recent industry reports, the market is projected to continue expanding at a robust pace, driven by the advantages offered by single-use systems over traditional multi-use setups.

Market Size and Growth

As of [latest available data], the single-use bioprocessing market was valued at [estimated value], with expectations of reaching [projected value] by [forecast year], growing at a CAGR of [growth rate]. This growth trajectory underscores the industry’s transition towards adopting disposable technologies in bioprocessing.

Products in the Single Use Bioprocessing Market

1. Bioreactors

Bioreactors are crucial components in bioprocessing, where they facilitate the growth of cells or microorganisms under controlled conditions. Single-use bioreactors have gained popularity due to their ease of use, quick turnaround times, and reduced cleaning and validation requirements compared to traditional stainless-steel bioreactors. These systems cater to both small-scale and large-scale biopharmaceutical production, thereby driving their adoption across the industry.

2. Mixers

Single-use mixers play a pivotal role in blending and mixing various components in bioprocessing workflows. These mixers are designed to be disposable, eliminating the need for cleaning and reducing the risk of product cross-contamination. Their flexibility and scalability make them suitable for a wide range of applications, from lab-scale research to commercial production.

3. Filtration Systems

Filtration is a critical step in bioprocessing to separate and purify biomolecules such as proteins, antibodies, and vaccines. Single-use filtration systems offer high efficiency, reliability, and sterility assurance while minimizing product loss and maximizing process yield. These systems include both depth filters and membrane filters, which are essential across various stages of biopharmaceutical manufacturing.

4. Chromatography Systems

Chromatography plays a vital role in purifying biomolecules based on their physicochemical properties. Single-use chromatography systems enable rapid purification with reduced operational complexities and lower costs compared to traditional column chromatography. These systems are scalable and adaptable, catering to diverse purification needs from lab-scale experiments to large-scale production.

Key Trends Driving Market Growth

1. Cost-Effectiveness and Operational Efficiency

Single-use bioprocessing technologies offer significant cost advantages by eliminating the need for extensive cleaning, sterilization, and validation associated with stainless-steel equipment. They also reduce downtime between batches, enabling faster turnaround times and increased production capacity.

2. Flexibility and Scalability

The modular design of single-use systems allows biopharmaceutical manufacturers to scale production according to demand quickly. This flexibility is crucial in the context of personalized medicine and the growing trend towards smaller batch sizes and diverse product portfolios.

3. Regulatory Support and Compliance

Regulatory bodies, including the FDA and EMA, have recognized the benefits of single-use bioprocessing technologies in ensuring product safety, quality, and consistency. This support has accelerated the adoption of these technologies across the biopharmaceutical industry.

4. Technological Advancements

Ongoing innovations in material science, sensor technologies, and automation are further enhancing the performance and reliability of single-use bioprocessing systems. Integrated sensors and data analytics capabilities are improving process control and monitoring, thereby optimizing bioprocess outcomes.

Regional Insights

Geographically, North America and Europe currently dominate the single-use bioprocessing market due to their established biopharmaceutical industries, robust regulatory frameworks, and early adoption of innovative technologies. However, Asia-Pacific is expected to witness the fastest growth during the forecast period, driven by increasing investments in biotechnology research, expanding biopharmaceutical manufacturing capabilities, and supportive government initiatives.

Challenges and Future Outlook

Despite the significant advantages, the single-use bioprocessing market faces challenges such as concerns over leachables and extractables, limited compatibility with certain processes, and the environmental impact of disposable plastics. Addressing these challenges through continuous research and development efforts will be crucial for sustaining market growth while ensuring environmental sustainability.

Looking ahead, the single-use bioprocessing market is poised for continued expansion, fueled by technological advancements, increasing biopharmaceutical production, and evolving regulatory landscapes. As industry players innovate and collaborate to overcome existing challenges, the adoption of single-use bioprocessing technologies is expected to become more widespread, shaping the future of biopharmaceutical manufacturing globally.